Handcrafted Book and Album Crates from Reclaimed American Chestnut

Rare Bird Reclaimed invites you to hold history in your hands with our artisan crates, crafted from the reclaimed wood of barns and outbuildings once built with the iconic—and now functionally extinct—American chestnut tree. These crates aren’t just storage; they are a celebration of the tree that once defined the Appalachian landscape, providing strength, shelter, and sustenance to generations.

By transforming this rare and historic wood into beautiful, functional pieces for books and vinyl records, we honor the chestnut’s enduring legacy while promoting sustainability. Each crate represents the power of preservation, breathing new life into forgotten materials and connecting the past to the present in a tangible, meaningful way.

Perfectly aligning tradition with the mission of Rare Bird Farm, these crates embody the art of restoration and the beauty of Appalachia’s heritage. Want to join us in preserving this incredible story? Contact us to secure your place on the list for our first crate shipments, arriving February 2025.

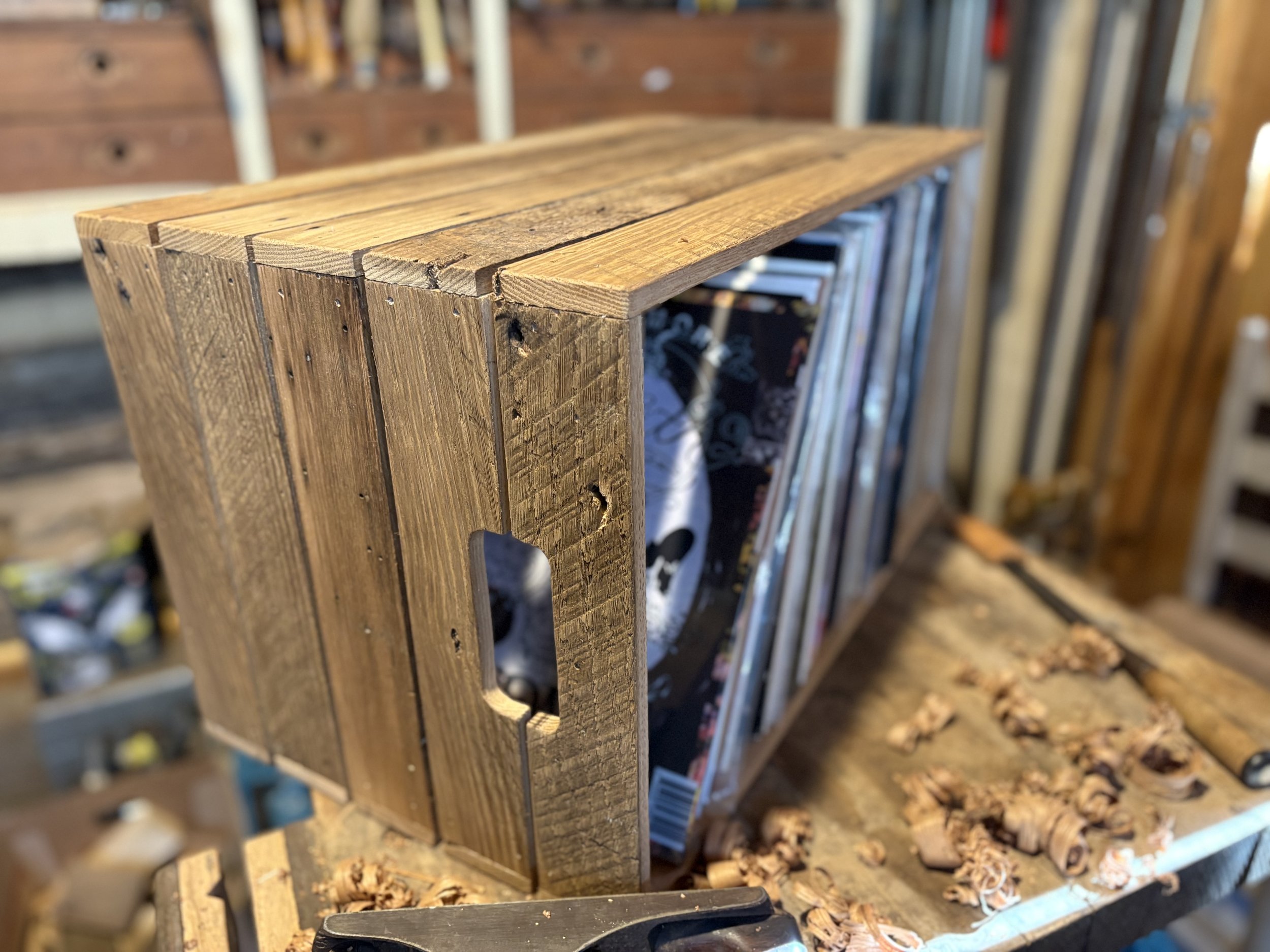

Custom built book & album crates made from salvaged wood of the extinct American chestnut tree

Crates will be available for order in Feb 2025

Carpenter and Rare Bird Farm partner Edwin Self with an album crate